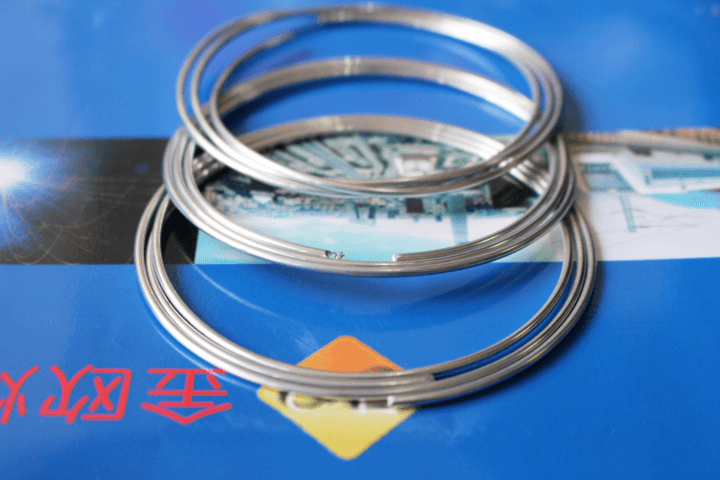

Short-circuit metal transfer provides negligible heat, making it the most suitable choice when welding sheet metal. Welding 304 stainless steel requires either ER308, ER308L, or ER308LSI wires, while aluminum will need a general-purpose ER4043 aluminum wire. We recommend AWS classification ER70S6 wire that produces a good weld arc without spatter as an excellent all-around choice. In addition, you will need to match the composition of the MIG wire to the base metal. Therefore, for metals up to 18 gauge, you will need a smaller diameter wire, such as. Remember that the filler wire diameter shouldn't be thicker than the base metal. Welding Wire For Thin Metalsīesides the welder, you will need a suitable filler metal when welding thinner material. Aesthetically, you can achieve TIG welding results with your MIG machine. This feature pulses the heat of the welding arc, allowing you to control heat while providing excellent arc stability and low spatter. While this feature was reserved for high-end, expensive machines in the past, you can find it with the YesWelder YWM 211P Double Pulse MIG welder. One of the things that can significantly help in dealing with thin metal is the pulsed MIG. With MIG welders, that's most commonly 20-30 amps, so you want to go as low as possible with thin metals. For example, a 140 amp, 110V welder will be fine for metal up to 1/8", but you should pay attention to the lower end of welding output. When choosing a MIG welder for thin metal, you can look for something other than the most powerful machine. To prevent burn-through and wrapping of sheet metal, you will need a proper MIG welder, filler metal, and shielding gas.

#Flux core welding sheet metal how to

So without further ado, let's see what you need and how to MIG weld thin metal. When chosen right, each of these will limit the heat and allow you to control the weld puddle perfectly. Therefore, welding thin metal requires adequate equipment, preparation, and technique. Thin metal is not so forgiving, so even the slightest heat over the recommended can cause distortion, wrapping, or burn-through. The heat input is the main issue with sheet metal of 24 gauge up to 14 ga. Gas metal arc welding (GMAW or MIG) can be successfully used to weld thin metal, but as long as you take extra care.

Photo by welding_mani MIG Welding Sheet Metal Luckily, we saved you hours of grunt work and compiled a straightforward guide on how to deal with each one of these. However, it will take time, practice, and an understanding of the fundamentals.įirst, you should know that MIG welding deals well with thin and medium-thick metal but not so great with thick metal. MIG welding is a pretty easy process to master and perform, and once you get the hang of it, you can weld different thickness metal without any issues. How Does MIG Welding Deal With Different Thicknesses? We will explain how MIG deals with sheet metal, medium or "hobbyist" steel, and thick plates and what you will need to weld them successfully.īy the end of the article, you should understand where MIG welding shines and where it comes short. However, many beginners asked how to MIG weld different thickness metals, so we decided to help. The ease of use and versatility make this process suitable for different metals and thicknesses. MIG welding is one of the most straightforward processes, which makes it widely used by hobbyists and DIY lovers across the globe.

0 kommentar(er)

0 kommentar(er)